Ion Vapor Deposition

Cametoid Technologies has the largest Ion Vapor Deposition (IVD) dedicated facility in the world. We’ve earned our selection as a preferred supplier to the aerospace industry by keeping pace with innovations in materials. For example, Cametoid holds

a patent on the process for IVD coating of parts made of increasingly popular materials like composite, thermoplastic, and PEKK/PEEK.

Environmentally-friendly IVD Aluminum coatings applied in our vacuum chambers outperform cadmium in preventing corrosion. Aluminum coatings can also be used at higher temperatures (up to 950F) than cadmium (which is limited to 425F).

IVD aluminum can be applied to a variety of metals and composite materials of all shapes and sizes and is quickly replacing cadmium and other toxic coatings.

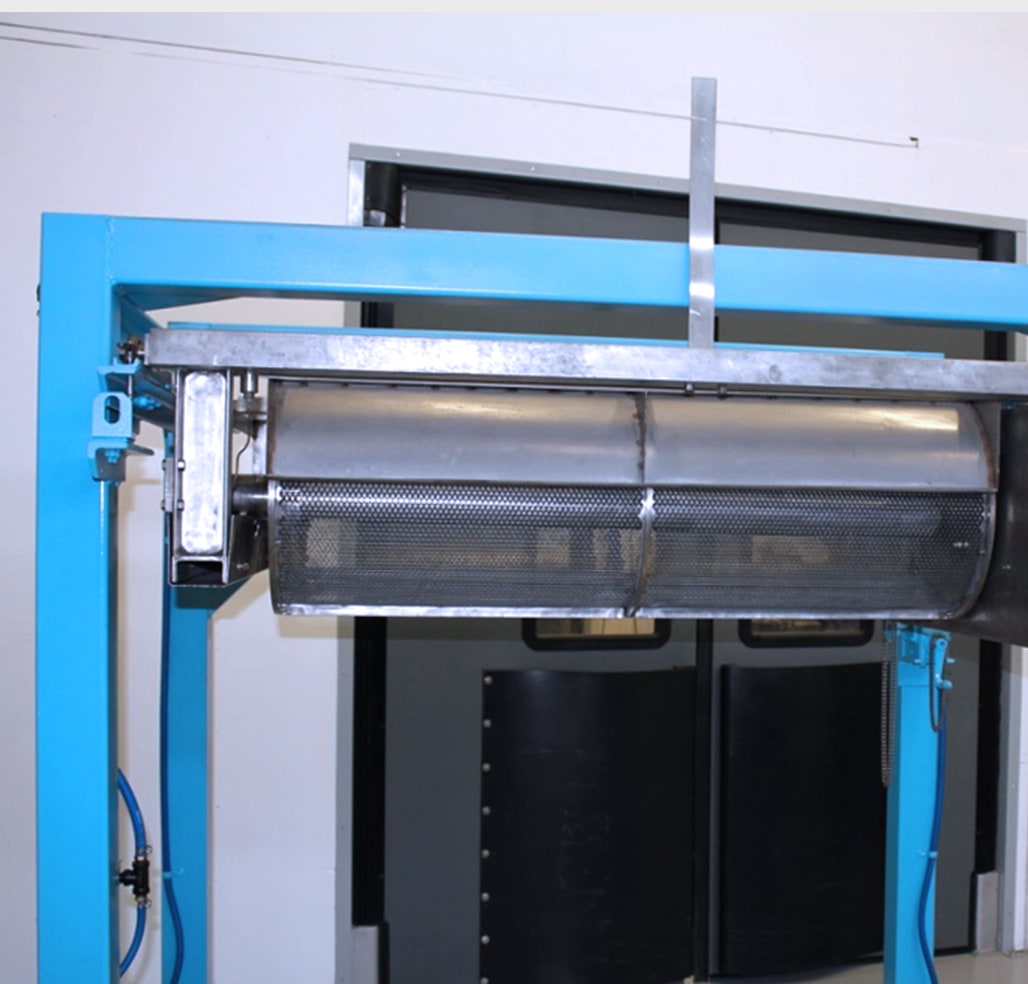

We offer Rack Coating of parts of all dimensions, shapes and sizes, and Barrel Coating of small parts and fasteners.

IVD Aluminum coatings:

- Are not penetrated by concentrated nitric acid;

- Protect most metals from galvanic corrosion;

- Will not cause hydrogen or liquid/heavy metal embrittlement of steel, titanium or nickel alloys;

- Are highly electrically conductive;

- Are stronger and last longer than aluminum anodizing;

- Are more cost-effective than cadmium plating when used on hardened steels;

- Can be used in contact with fuels (whereas cadmium plating cannot);

- Are EPA, OSHA, and engineering acceptable replacements for cadmium and cadmium nickel.

Cametoid uses the highest grade of aluminum available to ensure the quality of the coating. We also offer the fastest lead time in the industry.